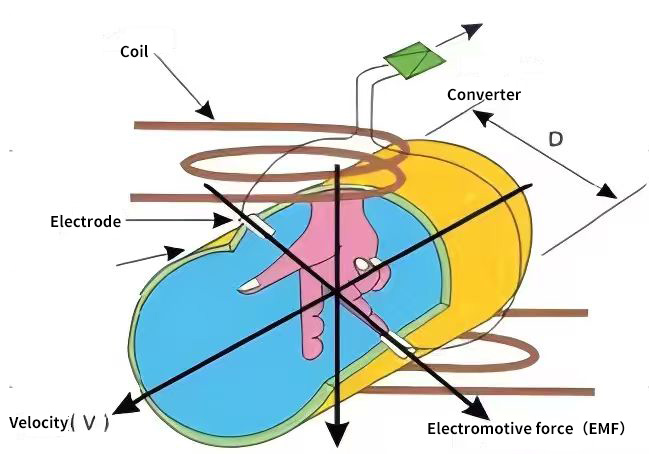

The electromagnetic flow meter consists of two parts: a sensor and a converter. Based on Faraday's Law of Electromagnetic Induction, it is a velocity-type meter used to measure the volume flow of conductive liquids. In addition to measuring the volume flow of general conductive liquids, it can also be used for measuring the volume flow of strongly corrosive liquids such as strong acids and alkalis, as well as homogeneous liquid-solid two-phase suspension liquids like mud, ore pulp, and paper pulp.

| Measurement accuracy | Class 0.2, Class 0.5 |

| Power supply | AC220±20%, 50Hz; 24VDC; or power supply methods such as lithium battery and solar energy. |

| Protection class | General type, waterproof type, explosion-proof type, and sanitary type. |

| Sensor body material | Cast aluminum, cast steel, stainless steel. |

| Power consumption | ≤0.65W. |

| Measured fluid | Conductive liquids with conductivity ≥0.5μs/cm. |

| Ambient temperature | -25℃~60℃; |

| Humidity | 5%~90%. |

| Medium flow velocity range | 0.3m/s~12m/s. |

| Protection class | IP65, IP67, IP68. |

Electrode structure | A. Standard electrodes: 3 electrodes (≤DN500), 5 electrodes (≥DN600); B. Scraper-type cleanable electrodes (DN≥350). |

| Electrode material: | 316 stainless steel, Hastelloy B, Hastelloy C, tantalum, titanium, platinum, tungsten carbide. |

| Lining material | Neoprene rubber (CR), polytetrafluoroethylene (F4/PTFE), perfluoroethylene-propylene (FEP), polyurethane rubber (PU), Teflon PEA, PO, etc. |

| Sensor housing material: | Painted steel plate (or stainless steel housing) |

| Grounding | When the pipeline grounding condition is poor (including insulated pipelines), grounding rings should be installed on both sides of the sensor. If the medium has strong abrasiveness, necked grounding rings that protect the lining should be selected. |

Standard rated pressure of the meter | DN10-DN50: 4.0MPa; DN65-DN150: 1.6MPa; DN200-DN500: 1.0MPa; DN600-DN2000: 0.6MPa; DN2200-DN3200: 0.25MPa. |

Note: Non-standard rated pressure can be customized. | |

According to Faraday's Law of Electromagnetic Induction, a pair of detection electrodes is installed on the pipe wall, which is perpendicular to the axis of the measuring tube and the magnetic field lines. When the conductive liquid moves along the axis of the measuring pipe, it cuts the magnetic field lines to generate an induced electromotive force. This induced electromotive force is detected by the two detection electrodes, and its value is proportional to the flow velocity, calculated by the formula:

E = B·V·D·K

E = Induced electromotive force;

K = Coefficient related to magnetic field distribution and axial length;

B = Magnetic induction intensity;

V = Average velocity of the conductive liquid;

D = Electrode spacing (inner diameter of the measuring pipe).![]()

The sensor transmits the induced electromotive force E as a flow signal to the converter. After signal processing such as amplification, conversion, and filtering, the converter displays the instantaneous flow and cumulative flow on a backlit dot-matrix LCD screen.

The UUv-20 series electromagnetic flow meters include various types such as general-purpose, slurry-type, wide-range ratio, ultra-low flow rate, filling-type, low-conductivity, and energy meters.

They are widely used in flow measurement in industrial sectors including petroleum, chemical engineering, metallurgy, light industry and textiles, papermaking, environmental protection, and food, as well as in fields such as municipal management, water conservancy construction, and river dredging.

Supports bidirectional flow measurement.

Provides multi-segment nonlinear correction of the sensor, sensor zero correction, and automatic zero calibration.

Features a user-friendly English interface with simple and clear operation.

Equipped with multi-level password management and setting functions for various limit alarm parameters.

Has a self-inspection function for the converter.

Adopts an integrated and split combined design, with dual coefficient setting for the converter and sensor, enabling the replacement of the converter.

Multiple output interfaces available: active or passive frequency output, cumulative pulse output; the converter has 4~20mA output, alarm output, and frequency output, and is equipped with communication interfaces such as RS-485, supporting fieldbus communication methods like PROFIBUS-DP and HART, or remote signal transmission such as GPRS and NB-IoT wireless remote transmission.

Contact Huaqiang for Wholesale Water Treatment Equipment