Hydrophobic PTFE pleated filter cartridges adopt polytetrafluoroethylene (PTFE) filter membranes, which have excellent chemical resistance, corrosion resistance, and inherent hydrophobicity. They strictly control the leaching of metal ions and are suitable for sterile filtration of most chemicals, organic solvents, and compressed air.

Outer Diameter | 69mm |

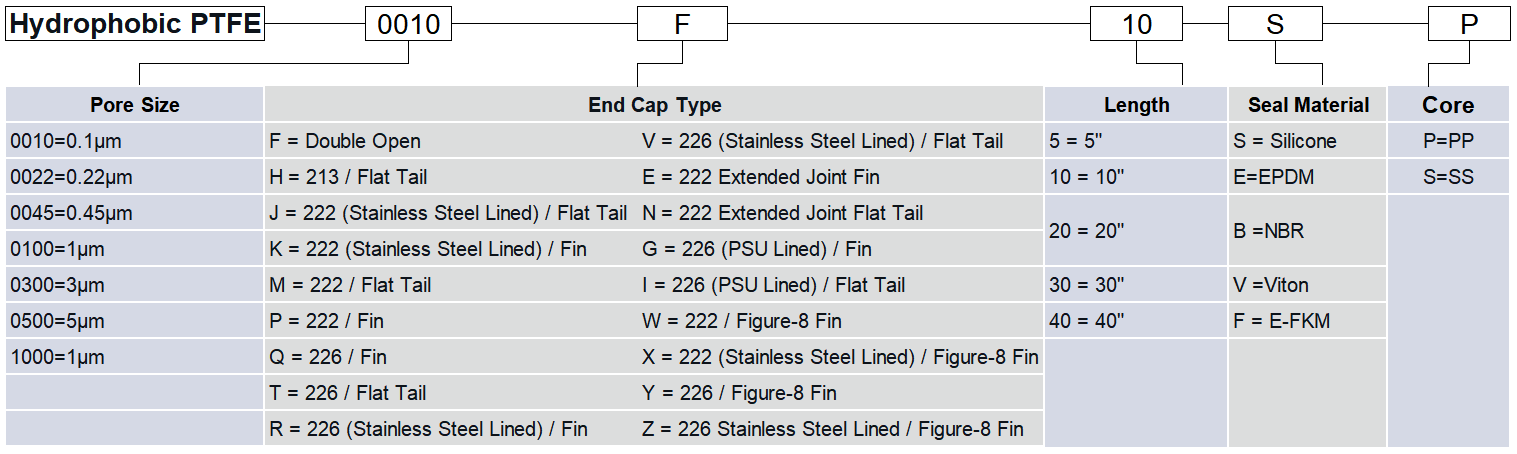

| Length | 5”, 10”, 20”, 30”, 40 |

Filter Material | Hydrophobic PTFE Membrane |

| Flow Guide Layer | Polypropylene (PP) |

| Core/Housing/End Cap | Polypropylene (PP) |

| Seal Ring | Refer to the Order Information Selection Table |

Maximum Operating Temperature | 80℃ |

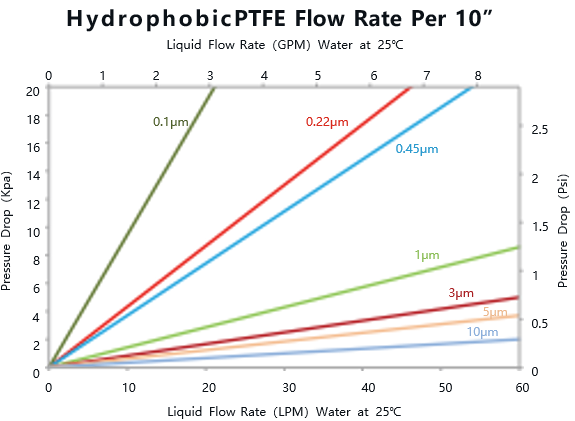

| Maximum Operating Pressure Differential | Forward 4.0 Bar @ 20℃; Forward 2.0 Bar @ 80℃ |

The filter cartridge uses a hydrophobic PTFE filter membrane, which has excellent chemical compatibility and can resist most chemicals.

The PTFE filter membrane has excellent particle-trapping ability, with a particle interception efficiency of up to 99.99%.

Produced in a clean workshop, ensuring high cleanliness.

100% integrity testing before leaving the factory to ensure the integrity of the filter cartridge.

Venting of sterile storage tanks

Sterile filtration of solvents: butyl acetate, ethyl acetate, various lipids, as well as various alcohols such as acetone, dimethyl sulfoxide, methanol, ethanol, and isopropanol

Sterile filtration of compressed air: air, nitrogen, and feed for bioreactors

Contact Huaqiang for Wholesale Water Treatment Equipment