Electrodeionization (EDI) is a modern membrane separation technology created through the seamless integration of electrodialysis and ion exchange. Its most prominent feature is the dynamic "electrical regeneration" of the ion exchange resins filled in the compartments, achieved by utilizing the H⁺ and OH⁻ ions generated from water dissociation.

Contaminants in the feed water negatively impact the membrane stack's desalination performance, increase maintenance requirements, and shorten the overall service life of the stack. Therefore, pretreatment (specifically Reverse Osmosis, or RO) of the EDI feed water is a primary condition for the system to achieve optimal performance and minimize equipment failures.

Requirements for Inlet Water Quality Indexes of EDI Module

Parameter | Unit | Operating Range | Optimal Performance |

Conductivity of Inlet Water | µs/cm | 1-20 | 1-6 |

Inlet Water Temperature | ℃ | 5-40 | 20-30 |

Inlet Water Pressure | MPa | 0.15-0.69 | 0.15-0.5 |

Total CO₂ | mg/L | <5 | <2 |

PH Value | 5.0-9.5 | 7.0-7.5 | |

Total Hardness (as CaCO₃) | ppm | ≤ 1.0, Recovery Rate 90% | <0.5 |

Reactive Silica (SiO₂) | ppm | ≤ 0.5 | ≤ 0.2 |

Total Organic Carbon (TOC) | ppm | ≤ 0.5 | Not Detected (ND) |

Total Chlorine | ppm | ≤ 0.05 | Not Detected (ND) |

Fe, Mn, H2S | ppm | ≤ 0.01 | Not Detected (ND) |

Oxidizing Agent | Not Detected (ND) | Not Detected (ND) | |

Chromaticity | APHA | <5 | |

Turbidity | NTU | <1.0 | |

Oil/Grease | Not Detected (ND) | Not Detected (ND) |

Note: The Inlet water for EDI modules must be RO product water or water of equivalent quality

The flow rate range of EDI modules is from 2.4 m³/hr to 9.5 m³/hr. Each model of module has a recommended flow rate range. EDI membrane stacks can be arranged in parallel to form a pure water treatment system suitable for any water treatment volume. Depending on the feed water and operating conditions, the modules can produce ultrapure water with a resistivity of over 16-18 MΩ·cm.

Table of EDI Module Operating Parameters

EDI Module Model | 3T | 5T | 7T | 8T |

Product Water Flow Rate Range (m3/h) | 2.4-4.2 | 4.0-6.4 | 5.0-8.5 | 6.0-9.5 |

Nominal Product Water Flow Rate (m3/h) | 3.0 | 5.0 | 7.0 | 8.0 |

Product Water Resistivity (MΩ·cm) | ≥ 16 | ≥ 16 | ≥ 16 | ≥ 16 |

Recovery Rate( %) | 90-95 | 90-95 | 90-95 | 90-95 |

Power Supply Voltage (VDC) | 0-500 | 0-500 | 0-500 | 0-500 |

Power Supply Current (A) | 0-6 | 0-6 | 0-6 | 0-6 |

Normal Operating Current (A) | 0.5-5.0 | 0.5-5.0 | 0.5-5.0 | 1.5-5.0 |

Inlet Water Pressure Range (MPa) | 0.1-0.69 | 0.1-0.69 | 0.1-0.69 | 0.1-0.69 |

Inlet/Product Water Pressure Drop (MPa) | 0.15-0.35 | 0.15-0.35 | 0.15-0.45 | 0.15-0.45 |

Concentrated Water Pressure Drop (MPa) | 0.05-0.15 | 0.06-0.20 | 0.08-0.25 | 0.08-0.25 |

Temperature Range (℃) | 5-40 | 5-40 | 5-40 | 5-40 |

Inlet Water pH | 4-11 | 4-11 | 4-11 | 4-11 |

Table of EDI Module Performance Parameters

EDI Module Model | 3T | 5T | 7T | 8T |

Nominal Product Water Flow (m³/h) | 3.0 | 5.0 | 7.0 | 8.0 |

Product Water Flow Range (m³/h) | 2.4-4.2 | 4.0-6.4 | 5.0-8.5 | 6.0-9.5 |

Weight (Wet) (/kg) | 105 | 135 | 137 | 155 |

Length × Width × Height (mm) | 460*300*610 | 645*300*610 | 645*300*610 | 815*300*610 |

Dimensions of Fresh Water Inlet/Outlet (inch) | 1.0” | 1.0” | 1.25” | 1.25” |

Dimensions of Concentrated Water Inlet/Outlet (inch) | 1/2” | 1/2” | 1/2” | 1/2” |

Dimensions of Electrode Water Outlet (inch) | 1/4” | 1/4” | 1/4” | 1/4” |

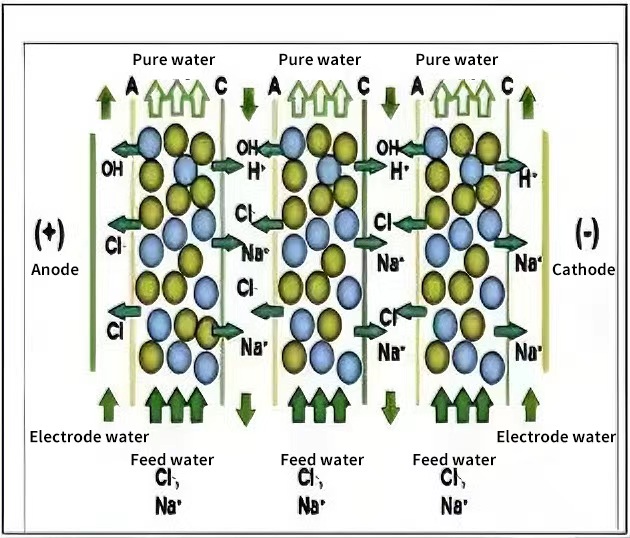

The working principle of EDI consists of three parts:

1) Electrodialysis process;

2) Ion exchange process;

3) Electrochemical regeneration process,

as shown in Figure 1

Figure 1: Schematic Diagram of the Working Principle of Huaqiang Environment Series EDI Membrane Stacks

Compared with products of other brands, Huaqiang Environmental EDI modules have the following technical features:

The counterflow design of the pure water compartment and concentrated water compartment can effectively prevent scaling in the concentrated compartment.

Modules with a fully filled concentrated water compartment design do not require concentrated water circulation.

Unique separate discharge system for electrode water, facilitating concentrated water recovery;

All-alloy cation and anion membrane sheets ensure the lowest operating voltage, which results in highly significant energy-saving benefits.

Quick-plug design for the power supply, making wiring easier.

Special sealing design ensures no water leakage even when the membrane stack pressure reaches 100 PSI;

Unique design of extra-large pure water and concentrated water frames ensures a higher quality of the effluent from the membrane stack

Contact Huaqiang for Wholesale Water Treatment Equipment