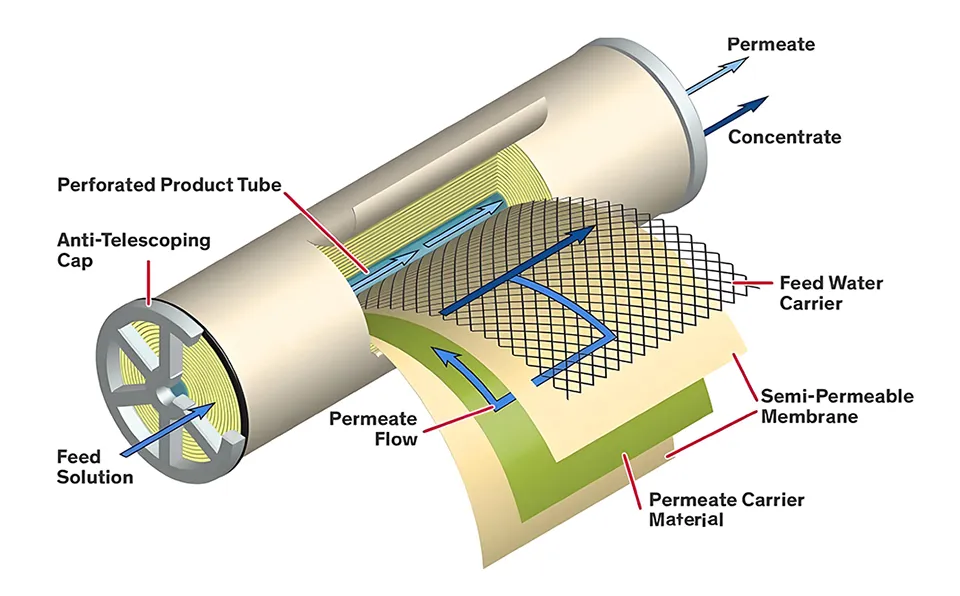

Reverse osmosis (RO) membranes are artificial semipermeable membranes made by simulating biological semipermeable membranes, and are the core components of reverse osmosis technology. Their pore size is extremely small (0.5-10 nm), and they realize the separation of solvents and solutes through pressure driving, which can effectively remove impurities such as dissolved salts, colloids, microorganisms, and organics in water.

Reverse osmosis (RO) membranes are artificial polymer membranes based on RO technology. They realize the selective separation of dissolved salts, organics, and other impurities in water through high-pressure driving, and are widely used in seawater desalination, industrial pure water preparation, and other fields.

Reverse osmosis (RO) membranes are artificial polymer membranes made by simulating biological semipermeable membranes, mainly composed of materials such as cellulose acetate and aromatic polyamide. Their core function is to realize the separation of solutes (such as salts, heavy metals) and solvents under pressure driven through physical screening and electrochemical repulsion.

Pore size screening: The membrane pore size is approximately 0.0001 μm. This size selectively allows only water molecules and trace amounts of small ions to pass through, effectively rejecting (intercepting) bacteria, viruses (with an approximate size of 0.5 μm), and macromolecular pollutants.

Pressure driving mechanism: Under the action of an external force that exceeds the solution's osmotic pressure, water molecules are forced through the membrane, moving against the natural osmotic direction. Consequently, pollutants are concentrated and discharged via the reject stream.

Dry-closed wet-open model: The membrane pores remain closed when dry and swell open when wet. This characteristic ensures optimal filtration precision and stability.

The daily maintenance of RO systems mainly includes three core measures: low-pressure flushing, shutdown protection, and chemical cleaning, which need to be comprehensively managed in combination with real-time water quality monitoring and parameter adjustment.

1. Low-pressure flushing:

Remove dirt on the membrane surface through regular high-flow, low-pressure flushing. When the inlet SDI (Silt Density Index) exceeds 5.5, low-pressure flushing must be performed immediately; in daily maintenance, it is recommended to flush once every 3-7 days, and shorten to once every 2 days when the water temperature exceeds 20℃.

2. Shutdown protection:

For short-term shutdown (≤7 days), low-pressure flushing must be performed daily and the inlet and outlet valves must be closed; for long-term shutdown (>7 days), a formaldehyde solution (0.5-1.0%) must be prepared to circulate and soak the membrane elements, and the operation must be repeated every 5 days.

3. Chemical cleaning:

The regular cleaning cycle is 3-12 months. If cleaning is required every month, the pretreatment system must be optimized. The cleaning plan must match the cleaning agent according to the type of pollutants (such as inorganic scaling, biological pollution). After cleaning, the recovery of produced water volume and desalination rate must be monitored.

4. Operating parameter monitoring:

Real-time monitoring of produced water volume, pressure difference, conductivity, and other parameters is required. When the pressure difference increases or the produced water volume decreases by more than 10%, low-pressure flushing must be performed immediately; if the pressure difference continues to increase, chemical cleaning is required.

Contact Huaqiang for Wholesale Water Treatment Equipment