PVDF material, featuring excellent chemical cleaning resistance and superior oxidation resistance.

High filtration precision, with a nominal pore size of ≤0.03 μm and uniform pore size distribution.

High strength and good toughness of membrane filaments (the elongation rate of membrane filaments exceeds 100%).

Low pressure and high flux (the design flow rate can be achieved under very low transmembrane pressure difference).

Excellent chemical stability (the performance of the membrane module remains unchanged after 50 cycles of acid-base chemical cleaning).

Strong anti-fouling capability (the cleaning cycle is extended by 30%, and the membrane flux recovery effect is good).

External-pressure operation, featuring a strong foulant-holding capacity and wide adaptability to influent water quality.

Standard fitting connection method, greatly improving the convenience of module installation.

PDF Download

PDF Download

| Membrane Type | External-pressure hollow fiber | |

| Membrane Material | PVDF (Polyvinylidene Fluoride) | |

| Shell Material | UPVC | |

| Nominal Membrane Pore Size (μm) | <0.03 | |

| Inner/Outer Diameter of Membrane Fiber (mm) | 0.7x1.3 | |

| Specification Model | HQUF-2860 | HQUF-2880 |

| Module Net Weight + Water Weight (KG) | 40+40 | 50+50 |

| Effective Membrane Area (m²) | 55 | 77 |

| Overall Dimension (mm) | 225x1860 | 225x2360 |

| Inlet/Outlet Diameter | DN50 | DN50 |

| Design Flux at 0.1MPa/25℃ | 2-2.5m³/h | 3-3.5m³/h |

| Service Life | 3-5 years | |

| Turbidity of The Effluent (NTU) | ≤0.1 | |

| Effluent Water SDI | <3.0 | |

| TOC Removal Rate | 20%~60% | |

| pH Range | 2~12 (during cleaning1~12) | |

| Maximum Feed Water Turbidity (NTU) | 300 | |

| Maximum Feed Water Pressure (MPa) | 0.5 | |

| Filtration Flux Range | 40~120L/(m²·h) (Select 0.1 MPa according to the Feed Water conditions.) | |

| Maximum Transmembrane Pressure Difference (MPa) | 0.2 | |

| Operating Temperature Range (℃) | 2-45 | |

| Maximum Feed Water Residual Chlorine Concentration (mg/L) | 200 | |

| Maximum Residual Chlorine Concentration in Cleaning Agent (mg/L) | 5000 | |

| Operation Mode | Dead-end filtration or cross-flow filtration | |

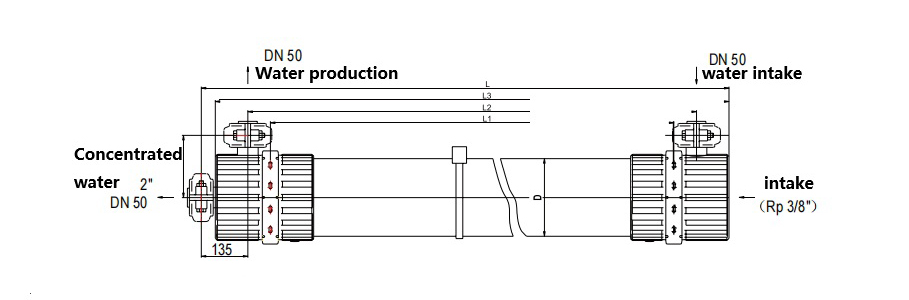

| Model | L(mm) | L1(mm) | L2(mm) | L3(mm) |

| HQUF-2860 | 1860 | 1500 | 1630 | 1820 |

| HQUF-2880 | 2360 | 2000 | 2130 | 2320 |

Note: Customization according to special requirements and specification dimensions of the membrane module is allowed.

Proper start-up is crucial for the stable operation of ultrafiltration. For ultrafiltration during the commissioning or after a long shutdown period, it is necessary to inspect and calibrate various equipment, instruments, and influent water quality before restarting, to ensure that all conditions meet the set values after commissioning. For specific operation steps and precautions, please refer to the product manual.

Under any circumstances, the ultrafiltration membrane components are not allowed to freeze. In special regions or under specific requirements, antifreeze shall be added to ensure transportation safety. For knowledge about antifreeze, please refer to the product manual.

The ultrafiltration membrane module must be used under the operating conditions specified in the product manual. Without written commitment or notification from Zhejiang Huaqiang Company, any non-rigorous design and use shall be deemed invalid and abandonment of the quality assurance.

Due to poor water quality, the ultrafiltration system's operating flow rate should be gradually increased to the design value. During the initial commissioning process, the initial flow rate should be set to 50% of the design flow rate and operated within 2~24 hours, especially for wastewater applications.

Some of the above data are test values under certain raw liquid and usage environment conditions, reflecting the performance of Huaqiang membrane products. Huaqiang membrane guarantees the authenticity and accuracy of the data above.

Since the ultrafiltration membrane products used by customers may be applied to different water quality conditions, the data above refer to ranges rather than fixed values. Please consult the sales staff of Huaqiang Environment for any accurate design customizations.

Contact Huaqiang for Wholesale Water Treatment Equipment