The side-mounted magnetic flap level meter (hereinafter referred to as the level meter) is suitable for detecting the liquid level of liquid media in various pressure-bearing (or open) liquid storage equipment (towers, cylinders, tanks, spherical containers, and boilers) in industrial production processes. It can display the working status and liquid level height of various liquids on-site. Equipped with a level transmitter, it can remotely transmit the liquid level position signal and achieve automatic control and level measurement through certain electrical devices.

The side-mounted magnetic flap level meter is a detection instrument with reliable safety. Due to its magnetically coupled, isolated, and sealed structure, it is especially suitable for liquid level detection of flammable, explosive, corrosive, and toxic liquids. Thus, the liquid level detection method in complex environments becomes simple, reliable, and safe. The side-mounted magnetic flap level meter has the direct-reading characteristic of an on-site display. It does not require the combination of multiple level meters and can perform full-range measurement independently. It has the advantages of fewer openings in equipment, clear display, eye-catching marks, and intuitive reading. When the level meter is directly equipped with a display instrument, the intermediate transmission for signal detection in the system can be omitted, thereby improving its transmission accuracy.

The top-mounted magnetic flap level meter is suitable for various underground tanks, pools, and other containers, as well as containers where a side opening is not suitable for liquid level display. If equipped with supporting instruments, it can be used for remote detection to realize automatic control functions.

Ambient temperature | -20℃~80℃ |

Relative humidity | 5%~100% |

Ambient pressure | 86KPa~108KPa |

Measurement range | 0~12m (optional); 0~6m for high-pressure type |

Display accuracy | ±10mm |

Medium pressure | Ordinary type<0.5MPa~0.6MPa; Anti-corrosion type, heat-tracing type, anti-frost type, high-temperature type, explosion-proof type:<10MPa; High-pressure type, high-temperature and high-pressure type: 10MPa~25MPa; Top-mounted anti-corrosion type: ≤1.0MPa; |

Medium temperature | Ordinary type, anti-corrosion type, anti-frost type: ≤80℃; Explosion-proof type:<120℃; Heat-tracing type, high-pressure type: ≤200℃; High-temperature type, high-temperature and high-pressure type: 200℃~450℃; |

Medium density | ≥0.5g/cm³ |

Medium viscosity | ≤0.05Pa・S |

Wetted material | Float: Optional 304, 316L, plastic, 304 wrapped with PTFE, titanium alloy; Flap: Optional plastic panel, all-aluminum panel, vacuum panel, stainless steel panel, LED panel. |

Process connection | Connection method: Flange, thread (according to customer needs); Connection material: 304, 316/316L, 304 lined with F46, PP/PVC. |

Alarm switch | AC220V 0.5A or DC24V 0.8A; Switch type: Passive dry contact; Switch form: Normally open, normally closed, self-holding; Electrical life: >100,000 times (related to control power); Limit load current: 3A (partial specifications); Maximum contact resistance: 150mΩ; |

Transmitter output module | Output signal: 4~20mA/Hart/RS485; Load resistance: 500Ω (when powered by DC24V); Power supply: DC24V 50mA; Ambient temperature: -40℃~60℃; Accuracy: Measurement range 0~0.5m: Basic error ±2%; Measurement range 0.5~2m: Basic error ±1.5%; Measurement range >2m: Basic error ±1%; Outlet: M20×1.5; Explosion-proof form: Flameproof type ExdⅡCT6, intrinsic safety type ExiaⅡCT6; |

End accessories | Upper exhaust: Can be equipped with flat welding cap, flange, cock, ball valve according to requirements; Lower sewage: Can be equipped with flat welding cap, flange, cock, ball valve according to requirements. |

Protection class | IP66, IP67 |

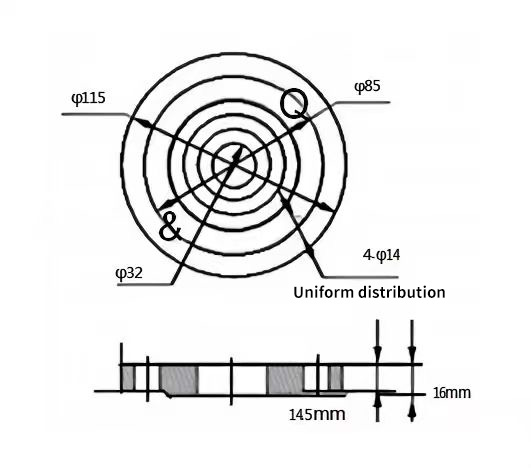

Note: The size of the connecting flange provided by our factory: DN20 and DN25 connecting flanges adopt the chemical industry standard HG/T 20592—20635—97. We can also customize the installation flange according to customer requirements. | |

No. | Type | Application Scope and Purpose |

1 | Ordinary Type | Widely used in petroleum, chemical, electric power, light industry, environmental protection and other sectors for continuous display of liquid level in open or pressure-bearing containers. |

2 | Anti-corrosion Type | Especially suitable for level measurement and indication of corrosive and toxic media. |

3 | Heat-tracing Type | Suitable for measuring liquids with high viscosity and easy crystallization. |

4 | High-temperature Type | Suitable for level measurement of liquid media in containers with pressure<10MPa and temperature between -200℃~450℃. |

5 | High-pressure Type | Suitable for measuring the liquid level of liquid media in closed containers at normal temperature with process pressure between 10MPa~20MPa. |

6 | High-temperature and High-pressure Type | Suitable for measuring the liquid level of liquid media in closed containers with temperature<200℃ and process pressure 10MPa<process pressure<20MPa. |

7 | Explosion-proof Type | Suitable for situations where electrical signals need to be transmitted remotely in flammable and explosive environments. This series of instruments is equipped with electronic devices such as level transmitters with 4-20mA current signals or upper and lower limit alarm settings. |

8 | Top-mounted Type | Suitable for various underground mobile medium storage tanks, and can display the liquid level on the ground. Not suitable for working occasions with strong vibration and strong magnetism. |

Note: For measuring media containing solid suspended impurities and ferromagnetic impurities, users can consider adding filtering devices. For level meters with transmitter output electrical signals, the medium temperature should not exceed 140℃.

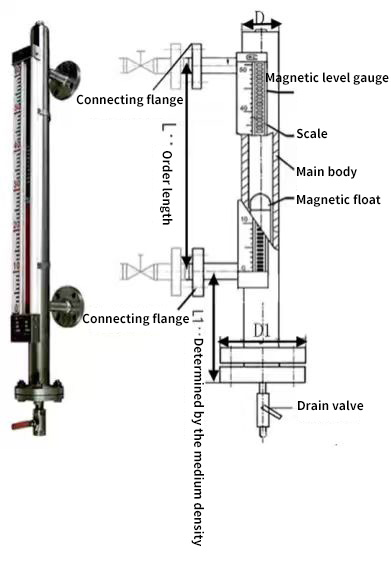

Side-mounted structure diagram:

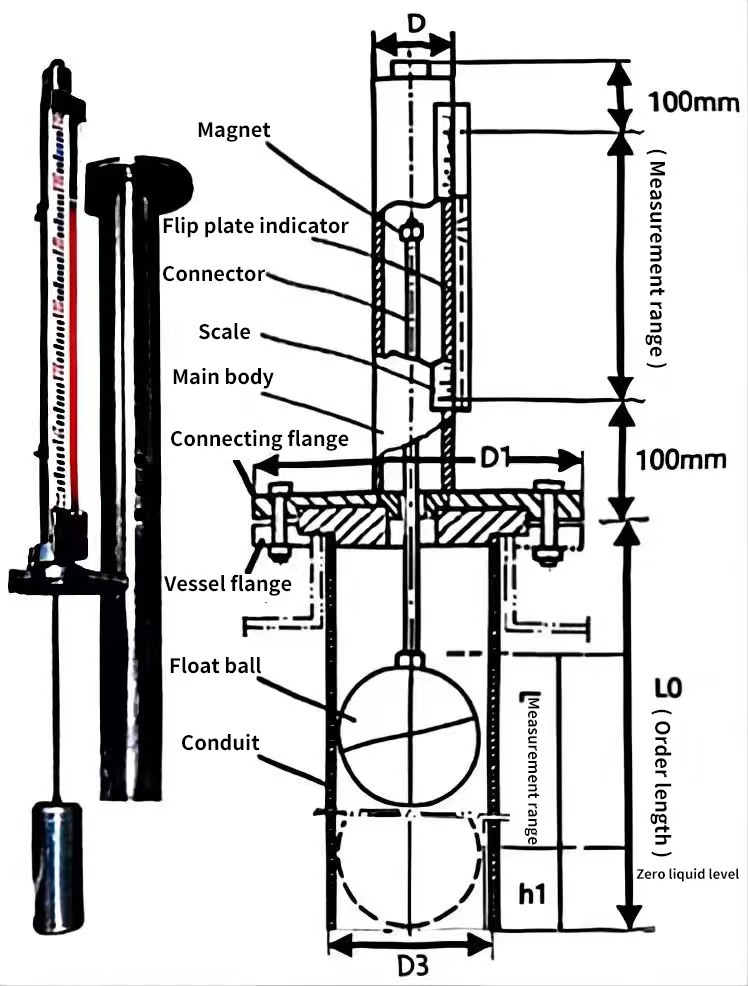

Top-mounted structure diagram:

Side-mounted flange specifications and dimensions:

L1 represents the center distance (in millimeters) of the installation connection pipes for the upper and lower parts.

With the changes in market demand, the company's products are constantly upgrading in quality and technology, improving production processes, and expanding the application fields and scope of magnetic flap level meters. In addition, the magnetic flap level meter has various output signals, enabling remote level indication, detection, control, and recording.

The magnetic flap level meter can be applied to almost all liquid level measurement and control in industrial automation process control. It is widely used in liquid level measurement, control, and monitoring in fields such as petroleum processing, municipal administration, food processing, chemical engineering, water treatment, pharmaceuticals, electric power, papermaking, metallurgy, shipping, and boilers.

Wide application range and diverse installation forms, suitable for measuring the liquid level and interface of any medium;

The measured medium is completely isolated from the indicating structure, with good sealing performance, leak prevention, suitable for liquid level measurement under high pressure, high temperature, and corrosive conditions, and high reliability.

Integrating on-site indication, remote transmission, alarm control switches, which can be adjusted freely, with complete functions; two-color indication with night light, continuous, intuitive, eye-catching, large measurement range, and the observation direction can be changed arbitrarily.

Good vibration resistance, able to work under conditions of large liquid level fluctuations; simple structure, convenient installation, and low maintenance costs.

Contact Huaqiang for Wholesale Water Treatment Equipment