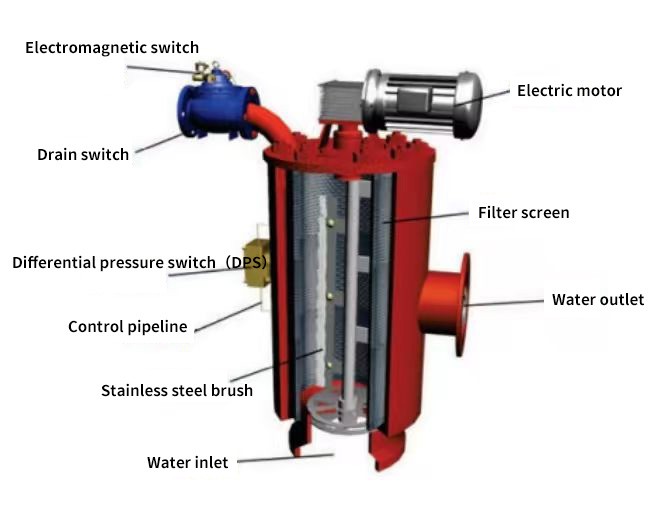

The self-cleaning filter is a precision device that uses a filter screen to directly intercept impurities in the water, purify the water quality, and ensure the normal operation of other equipment in the system.

Water enters the self-cleaning filter body through the water inlet. Thanks to the intelligent (PLC, PAC) design, the system can automatically identify the degree of impurity accumulation and send a signal to the blowdown valve for automatic blowdown.

The self-cleaning filter overcomes many shortcomings of traditional filtration products, such as low dirt-holding capacity, easy clogging by pollutants, the need for disassembly to clean the filtering element, and the inability to monitor the filter status.

It features the dual functions of filtering raw water and automatically cleaning and discharging pollutants from the filter element.

During the cleaning and blowdown process, the system maintains a continuous water supply, and it can monitor the filter's working status with a high degree of automation.

It covers various filtration precision requirements, from 50 μm to 3,000 μm, providing customers with a variety of water filtration equipment options.

Model | Tank Specification | Inlet & Outlet Specification | Maximum Flow Rate (t/h) | Precision Grade | Motor Power / Reducer Model |

HQ-250-50 | φ273*1000 | DN25-DN50 | 50 | ≥50μm | 0.18kw/RV040 |

HQ-300-100 | φ325*1200 | DN80-DN125 | 100 | ≥100μm | |

HQ-400-150 | φ426*1300 | DN150 | 200 | ≥200μm | 0.37kw/RV063 |

HQ-480-200 | φ480*1550 | DN200 | 300 | ≥300μm | |

HQ-530-250 | φ530*1650 | DN250 | 450 | ≥300μm | |

HQZ-600-300 | φ600*1750 | DN300 | 550 | ≥300μm | |

HQ-700-350 | φ700*2000 | DN350 | 700 | ≥500μm | 0.75kw/RV075 |

HQ-800-400 | φ800*2150 | DN400 | 1000 | ≥800μm | |

HQ-900-450 | φ900*2300 | DN450 | 1200 | ≥1000μm | |

HQ-1000-500 | φ1000*2500 | DN500 | 1500 | ≥1500μm | |

HQ-1100-600 | φ1100*2600 | DN600 | 1800 | ≥2000μm | 1,5kw/RV090 |

HQ-1200-700 | φ1200*2800 | DN700 | 2300 |

The water to be treated enters the filter body through the water inlet, and impurities in the water are deposited on the stainless steel wedge wire screen, which results in a pressure differential.

The differential pressure switch monitors the change in pressure differential between the water inlet and outlet. When the pressure differential reaches the set value, the electric controller sends signals to the control valve and the drive motor, triggering the following actions:

The motor drives the brush to rotate and clean the filter element, and simultaneously, the control valve opens for blowdown.

The entire cleaning process takes only tens of seconds. When cleaning is completed, the control valve closes, the motor stops rotating, the system returns to its initial state, and starts the next filtration cycle.

Simple structural design

Short backwashing time, large flow rate, and low pressure loss (≤0.018MPa)

Self-cleaning control modes include pressure difference, time, and manual control

The device can be connected to the DCS system

High-precision filtration, stable effluent quality, and blowdown water consumption < 1%

The filter screen can be used for life without replacement

Long service life

Suitable for different raw water qualities and water use requirements

It has few wearing parts, no consumables, low operating costs, and simple operation and management.

Continuous water supply during automatic backwashing.

Metallurgy: Continuous casting water, high-pressure phosphorus removal water, clean circulating water, full filtration and side filtration of cooling water, nozzle protection, etc.

Power Industry: Cooling water filtration for steam turbines, circulating ash water filtration for wet electrostatic precipitators, dust reduction nozzle protection, full filtration and side filtration of cooling tower water, etc.

Agriculture: Water treatment for sprinkler irrigation and drip irrigation.

Others: Iron and steel, petroleum, chemical, electronics, textile, papermaking, food, pharmaceutical, automotive industries, etc.

Contact Huaqiang for Wholesale Water Treatment Equipment