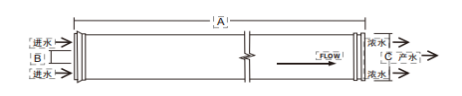

The HQ-RO-XFR anti-fouling membrane is a spiral-wound polyamide composite reverse osmosis membrane element. Its unique anti-fouling membrane technology endows it with excellent anti-fouling capability and cleanability.

While ensuring high salt rejection performance, it reduces energy consumption during operation and extends the cleaning cycle. It can perfectly replace anti-fouling brackish water membranes such as DuPont BW30XFR and Suez AG8040F.

Product Model | Effective Area ft2 (㎡) | Inlet Flow Channel Width (mil) | Water Production gpd (m³/d) | Stable Salt Rejection Rate (%) |

HQ-RO-4040XFR | 82 (7.6) | 34 | 2500 (9.5) | 99.7 |

HQ-R0-8040XFR | 400 (37.2) | 34 | 12000 (45.9) | 99.7 |

1. The water production and salt rejection rate are obtained based on the following standard test conditions: 2000 ppm NaCl, 225 psi (1.55 MPa), 77 ℉ (25 ℃), pH 8, 15% recovery rate.

2. The variation range of water production is +/-15%.

Maximum Operating Temperature | 45℃ |

Maximum Operating Pressure | 600psi (41bar) |

Maximum Pressure Drop | 1bar |

Continuous Operating pH Range | 2-11 |

Cleaning pH Range | 1-13 |

Maximum Inlet Flow SDI¹⁵ | 5 |

Maximum Influent Turbidity | 1NTU |

Maximum Residual Chlorine Concentration of Influent Water | <0.1ppm |

The wide flow channel reduces the probability of membrane fouling and improves the cleaning effect.

It has the widest pH cleaning range (1-13) in the industry and good chemical resistance, providing the most effective cleaning performance, stability and durability.

The TFC (Thin Film Composite) surface is coated with a super anti-pollution layer, which has excellent anti-pollution performance and a long service life.

The membrane has a high permeability and lower energy consumption.

Wastewater treatment and reuse, high-purity water preparation;

Food and pharmaceutical fields: food processing, pharmaceutical applications;

Municipal and resource development: seawater desalination, drinking water purification.

Contact Huaqiang for Wholesale Water Treatment Equipment